PRODUCTS

Databus Cables

- Integrated 9/11/18/20 Cores 0.75mmsq UIC Databus Cables

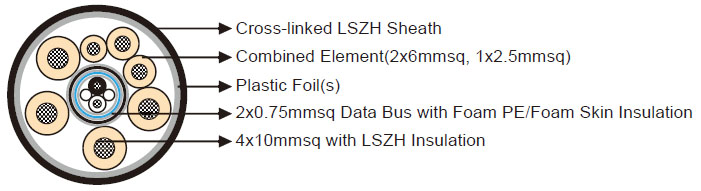

FRL-UIC-4G10+2G6+1G2.5+2G0.75

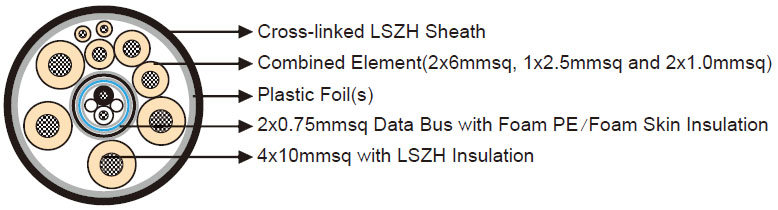

FRL-UIC-4G10+2G6+1G2.5+2G1+2G0.75

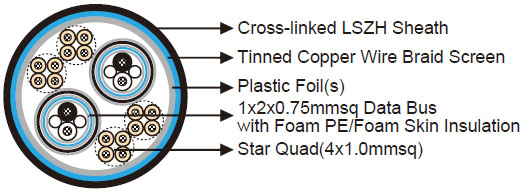

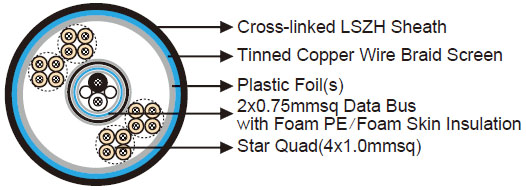

FRL-UIC-4Q1S+2G0.75/FRL-UIC-4Q1S+2P0.75S

Application :

- The cables are used as connecting cables to transmit digital signals inside railway rolling stocks.

Construction :

- For 9 cores UIC databus cables :

-

4 cores 10 mm2 stranded tinned copper conductor with LSZH insulation. Combined Element 3 cores (with Cu-strand 2 x 6mm2, 1 x 2.5mm2) are twisted with a filling element to a combined element. Core Wrapping Overlapped plastic-foil(s) Elements sheaths TPE UIC Data Bus 0.75mm2 Two foam PE or foam skin insulated tinned copper stranded conductors are twisted together with two filling elements to a pair. Core Wrapping Overlapped plastic-foil(s) Screen Tin plated copper braid Elements sheaths TPE Stranding 4 strands are twisted to a core together with 3 cored element, the UIC data bus and two fillers Core Wrapping Overlapped plastic-foil(s) Outer Sheath Cross-linked oil resistant LSZH compound -

- For 11 cores UIC databus cables :

-

4 cores 10 mm2 stranded tinned copper conductor with LSZH insulation Combined Element 5 cores (with Cu-strand 2 x 6mm2, 1 x 2.5mm2 and 2 x 1.0 mm2) are twisted with a filling element to form a combined element. Core Wrapping Overlapped plastic-foil(s) Elements sheaths TPE UIC Data Bus 0.75mm2 Two foam PE or foam skin insulated tinned copper r stranded conductors are twisted together with two filling elements to a pair Core Wrapping Overlapped plastic-foil(s) Screen Tin plated copper braid Elements sheaths TPE Stranding 4 strands are twisted to a core together with 5 cored element, the UIC data bus and two fillers Core Wrapping Overlapped plastic-foil(s) Outer Sheath Cross-linked oil resistant LSZH compound -

- For 18/20 cores UIC databus cables :

-

Star Quad Four LSZH insulated 1mm2 stranded tinned copper conductors are twisted to form a star quad UIC Data Bus 0.75mm2 Two foam PE or foam skin insulated tinned copper stranded conductors are twisted together with two filling elements to form a pair Core Wrapping Overlapped plastic-foil(s) Screen Tin plated copper braid Elements sheaths TPE Stranding 4 star quads are stranded together with 2 or 4 UIC data bus cable and several fillers Core Wrapping Overlapped plastic-foil(s) Screen Tin plated copper braid Outer Sheath Cross-linked oil resistant LSZH compound -

Electrical & Mechanical Properties :

-

Nominal Voltage 300V Maximum Temperature 90°C Minimum Temperature -40°C Bending Radius 12 x Overall Diameter

Chemical & Environmental Properties :

-

EN 60684-2 No fluorine EN 50305; EN 60811-2-1 Resistance to mineral oil & fuel oil, acid & alkali EN 50305 Resistance to ozone

Fire Performance for rolling stock application :

-

EN 50306-2 Hazard levels HL1, HL2/HL3, HL4 DIN 5510-2 Protection level 1/2/3/4 BS 6853 Interior use 1a, 1b, II; Exterior use 1a, 1b, II NF F 16-101 F0 EN45545-2 R15 Interior/ R16 Exterior HL1, HL2, HL3

Fire Performance in General:

-

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) Vertical flame propogation for a single insulated wire or cable EN 50266-2-4 + EN 50305; IEC 60332-3-24;

NF C 32-070 2.2 (C1); VDE 0472 Teil 804Vertical flame spread of vertically mounted bunched wires or cables EN 50268-2; IEC 61034-2; NF C 32-073 ;

NF C 20-902; NF F 16 101; VDE 0472 Teil 816Low Smoke Emission EN 50267-2-1; IEC 60754-1; NF C 32-074;

NF C 20-454; VDE 0472 Teil 815Halogen Free EN 50267-2-2/3; IEC 60754-2; NF C 32-074;

NF C 20-453; VDE 0472 Teil 813

Low Corrosivity (Acidity & Conductivity) EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853 Low Toxicity NF F 63 808; BS6853; NF F 16 101 Smoke index EN45545-2 Requirement for fire behavior of materials & components R15/R16

FRL-UIC-4G10+2G6+1G2.5+2G0.75 :

-

Nominal Cross Sectional Area Number &

Nominal

Diameter

of StrandsNominal

Sheath

ThicknessNominal

Overall

DiameterNominal

WeightMaximum

Conductor

ResistanceImpedance Maximum Attenuation 20°C @0.75-3MHz @1MHz @1.5MHz @2MHz @3MHz mm2 No/mm mm mm kg/km Ω/km Ω dB/km dB/km dB/km dB/km 0.75 19/0.22 1.8 25 917 26.7 120+/-12 10 13 14 18 10 80/0.4 1.95 - - - - - 6 84/0.3 3.39 - - - - - 2.5 37/0.29 8.21 - - - - -

FRL-UIC-4G10+2G6+1G2.5+2G1+2G0.75 :

-

Nominal Cross Sectional Area Number &

Nominal

Diameter

of StrandsNominal

Sheath

ThicknessNominal

Overall

DiameterNominal

WeightMaximum

Conductor

ResistanceImpedance Maximum Attenuation 20°C @0.75-3MHz @1MHz @1.5MHz @2MHz @3MHz mm2 No/mm mm mm kg/km Ω/km Ω dB/km dB/km dB/km dB/km 0.75 19/0.22 1.8 25 969 26.7 120+/-12 10 13 14 18 10 80/0.4 1.95 - - - - - 6 84/0.3 3.39 - - - - - 2.5 37/0.29 8.21 - - - - -

FRL-UIC-4Q1S+2G0.75 :

-

Nominal Cross Sectional Area Number &

Nominal

Diameter

of StrandsNominal

Sheath

ThicknessNominal

Overall

DiameterNominal

WeightMaximum

Conductor

ResistanceImpedance Maximum Attenuation 20°C @0.75-3MHz @1MHz @1.5MHz @2MHz @3MHz mm2 No/mm mm mm kg/km Ω/km Ω dB/km dB/km dB/km dB/km 0.75 19/0.22 1.8 18.5 498 26.7 120+/-12 10 13 14 18 1 19/0.25 20 - - - - -

FRL-UIC-4Q1S+2P0.75S :

-

Nominal Cross Sectional Area Number &

Nominal

Diameter

of StrandsNominal

Sheath

ThicknessNominal

Overall

DiameterNominal

WeightMaximum

Conductor

ResistanceImpedance Maximum Attenuation 20°C @0.75-3MHz @1MHz @1.5MHz @2MHz @3MHz mm2 No/mm mm mm kg/km Ω/km Ω dB/km dB/km dB/km dB/km 0.75 19/0.22 1.5 23 530 26.7 120+/-12 10 13 14 18 1 19/0.25 20 - - - - -

|

|

|

|

|

|

Corona Resistant |

Highly Flexible |

UV Resistant |

Ozone Resistant | Abrasion Retardant |

Cold- resistant |

|

|

|

|

|

|

Resistance To Soldering Heat |

Acid&Alkaline Resistant |

IRM 903 Fuel Oil Resistant |

IRM 902 Mineral Oil Resistant |

Fire Retardant NF C32-070-2.2(C2) IEC60332-3-24/EN50266-2-4 |

Flame Retardant NF C32-070-2.1(C1) IEC60332-1-2/EN50265-2-1 |

|

|

|

|

Low Toxicity NF X70-100/NF F63 808 TM1-04/BS 6853 |

Low Corrosivity IEC60754-2/EN50267-2-2/3 NF C32-074/VDE 0472-813 |

Low Smoke Emission IEC 61034-2 / EN 50268-2 NF C32-073/VDE 0472-816 |

Zero Halogen IEC 60754-1/EN 50267-2-1 NF C32-074//VDE 0472-815 |